How To Strengthen Thin Sheet Metal

Try rivets or brazing.

How to strengthen thin sheet metal. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Preparing to bend sheet metal with a vise. When spot welding for instance each spot weld causes the sheet to expand 360 degrees around the weld. The second is it benefits from the structural integrity that the wire hidden inside gives.

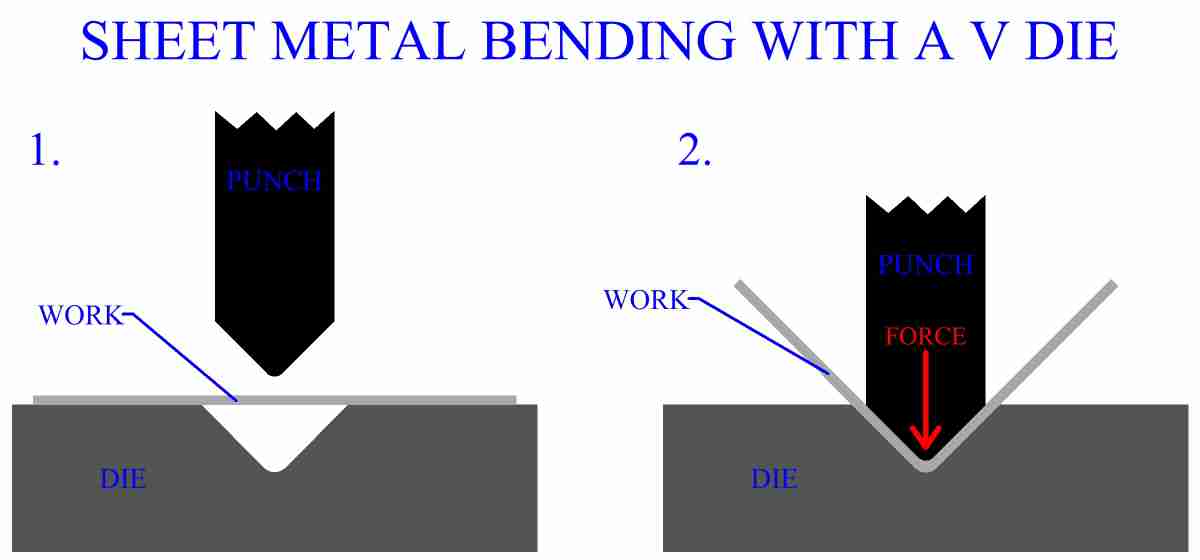

To create bends you can utilize a body hammer dolly or a metal brake. The punch is then. Now fold the edge of the metal over the metal wire. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

Beads or flared holes in the sheet metal add material in planes that are aligned with an axis in which the part would otherwise be weak. Rolling sheet metal edges with wire strengthens the panel in two ways that ordinary sheet metal bending doesn t. Heat causes metal to expand and warp if you re not careful. How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools.

Welding sheet metal isn t always the ideal way to join sheet especially thin or non ferrous sheet. One is that by metal being folded over itself it has doubled in thickness. The metal in the areas where holes and slots are punched gets stretched and become more tensile which gives more structural rigidity to the sheet metal. How to bend sheet metal without a brake.

In addition to strengthening sheet metal panel this method helps in enhancing the finish of the panel edges. Part 1 of 3. Wire edge this is done by putting a small piece of metal wire near the edge of the panel. That is they essentially allow a thin part to behave like a.

Place the die over the draw stud before inserting the stud through the pilot hole.